How To Prevent Heat Stroke While Welding

As a welder, you are probably used to high temperatures created by the welding arc, but things can get complicated during the summer. As the temperatures rise, you are exposed to extreme heat caused by the arc and environment combined.

Exposure to high temperatures causes heat stress, which is a serious condition that occurs once the body temperature rises over the optimal values, and the body cannot properly cool down. This condition causes fatigue, loss of concentration, and other heat-related illnesses, and in the final stages, heat stroke.

Since we are experiencing a severe heat wave this summer, in this article, we'll explain everything you need to know about heat stress and give you some tips on how to prevent heat stroke while welding.

What Is Heat Stress?

Heat stress is a serious condition that occurs once the body temperatures rise over 98º F. According to experts, this is the ideal body temperature for a human body to function at optimal performance. However, when welding in hot weather or intense heat, the temperature rises, so welders start to feel discomfort.

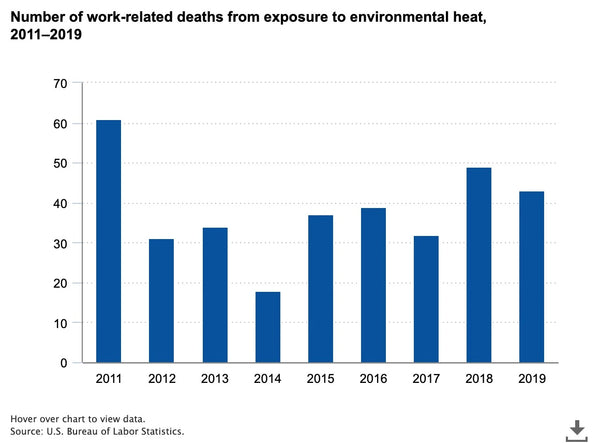

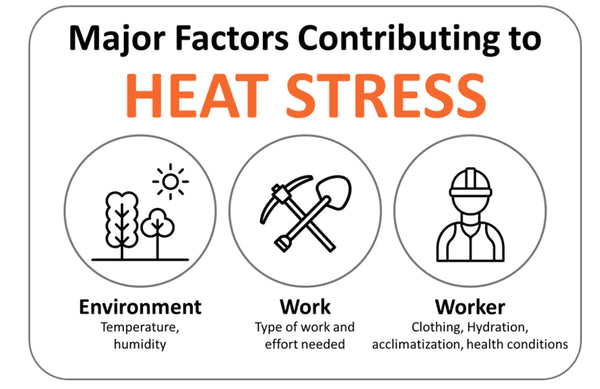

High heat can greatly reduce productivity and increase operator errors. Welders start to feel fatigued, heat cramps, heat exhaustion, and if not treated accordingly, heat exposure can lead to heat stroke. Stroke can be fatal, and according to the Bureau of Labor Statistics, from 2011-2019, there were 344 worker-related deaths in the U.S. due to environmental heat exposure.

Source: https://www.bls.gov/opub/ted/2021/43-work-related-deaths-due-to-environmental-heat-exposure-in-2019.htm

Even though all workers can suffer from heat exposure, the welding industry is recognized as highly risky in indoor and outdoor work. The reason is the added temperature of the arc, but also protective gear. The body uses sweat for heat dissipation, but due to all that bulky protective gear, the body cools slower. Since the body cools at a slower pace, the heat builds up, leading to different issues.

The Occupational Safety and Health Administration (OSHA) recognized the issues and, in 2022, launched a National Emphasis Program to protect millions of workers from heat illness and injuries. OSHA is aware of the issues of working in high-temperature environments and recommends solutions, but at the moment, there are no effective standards.

National Emphasis Program - Outdoor and Indoor Heat-Related Hazards

What Causes Heat Stress When Welding?

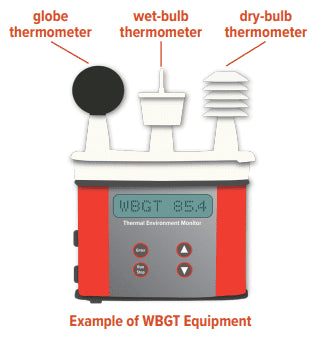

While you might think that high temperature is the leading cause of heat stress when welding, there are many factors that have a role in creating an occupational heat stress risk for welders. Besides the temperature, as a welder, you should be aware of the following:

- Environmental conditions

- Level of physical activities

- Use of clothing or protective gear

- Individual/personal risk factors.

Environmental conditions such as air temperature, humidity, radiant heat, and air movement can contribute to heat-related illness. As the humidity rises, the air is overwhelmed by moisture, so your body cannot get rid of excess heat by sweat. Radiant heat from sunlight, arc, or material preheating and post heating can also raise the overall body temperature. Low-air movement, or no wind, also raises the heat.

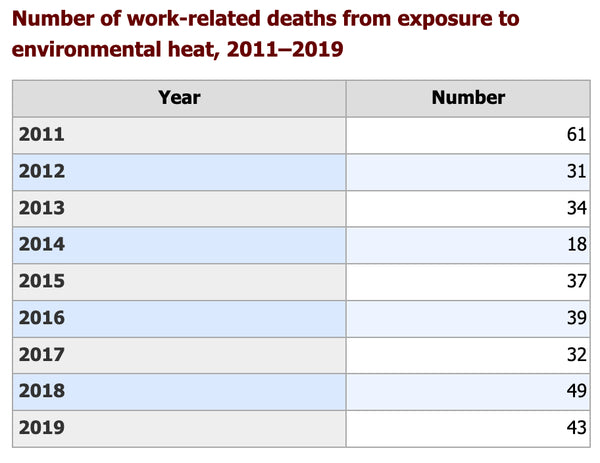

You can use various matters to measure workplace environmental heat, but OSHA recommends a wet bulb globe temperature (WBGT) monitor. WBGT measures all major environmental heat factors — temperature, humidity, radiant heat, and wind.

Metabolic heat rises as the physical activity of workers is greater. Sitting or standing with minimal arm and leg work causes significantly lower metabolic heat compared to intense activity at a maximum pace. Additionally, workers who are overweight or obese might produce more metabolic heat than other workers who perform the same tasks.

Personal equipment, similar to moisture, prevents heat dissipation. PPE is a must-have in welding, but long sleeves, helmets, and leather jackets during summer welding can significantly raise the internal heat and affect the welder's performance. You'll have to balance between proper protection from welding hazards and heat exhaustion.

Individual risks or personal factors, such as age, chronic illnesses, medication, weight, and more, can cause heat stress and other heat-related illnesses. As you get older, your central nervous system starts to deteriorate, and it’s harder to regulate body temperatures. Health conditions such as heart and lung diseases, medication, obesity, and previous history of heat stroke also can raise the risk of heat.

Source: https://slatesafety.com/what-is-heat-stress-and-what-causes-heat-injuries/

Heat-Related Illnesses

Feeling ill while welding in the heat is a serious warning sign. Even a moderate level of heat can cause first symptoms and less severe illnesses, but long-term exposure can cause heat stroke, which can be fatal. In order of severance (from lowest to highest), heat-related illnesses are:

- Heat rash is a skin irritation caused by excessive sweating during hot, humid weather. It is typically a cluster of small red blisters, but it is not a severe condition.

- Heat cramps usually affect welders who sweat a lot during welding. This sweating depletes the body’s salt and moisture levels. Low salt levels in muscles cause painful cramps, which can also be a symptom of heat exhaustion.

- Heat syncope is a fainting episode or dizziness that usually occurs when standing for too long or suddenly standing up after sitting or lying. Welders suffer from syncope due to dehydration and lack of acclimatization.

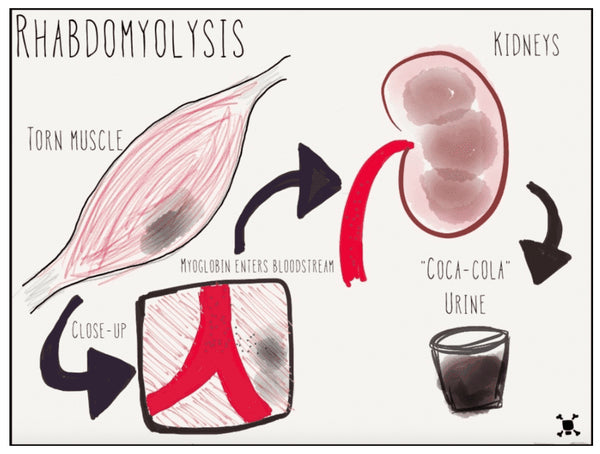

- Rhabdomyolysis (rhabdo) is a medical condition associated with heat stress and prolonged physical exertion. Rhabdo causes the rapid breakdown, rupture, and death of muscles. When muscle tissue dies, electrolytes and large proteins are released into the bloodstream. This can cause irregular heart rhythms, seizures, and damage to the kidneys.

Source: https://www.emdocs.net/emdocs-cases-evidence-based-recommendations-for-rhabdomyolysis/

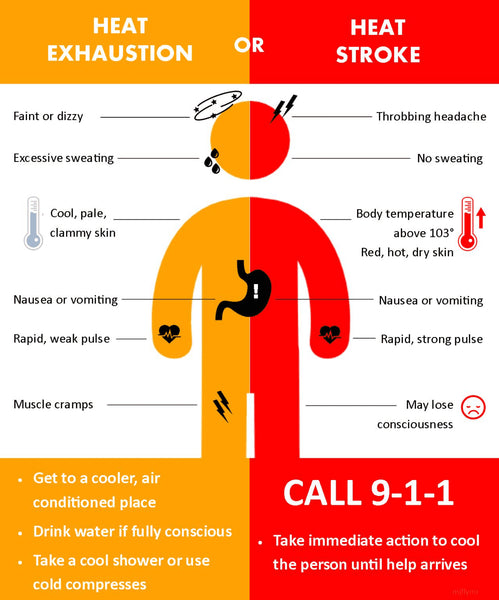

- Heat exhaustion is the body’s response to an excessive loss of water and salt, usually caused by excessive sweating. This condition is more common for older welders and welders with high blood pressure.

- Heat stroke is the most severe heat-related illness. A stroke occurs when the body can no longer control its temperature. As a result, the temperature rises rapidly, the sweating mechanism fails, and the body cannot cool down. During the stroke, the body temperature can rise to 106°F or higher within 10 to 15 minutes. Heat stroke can cause permanent disability or death if the person does not receive emergency treatment.

Welding in the Summer - How to determine the risks

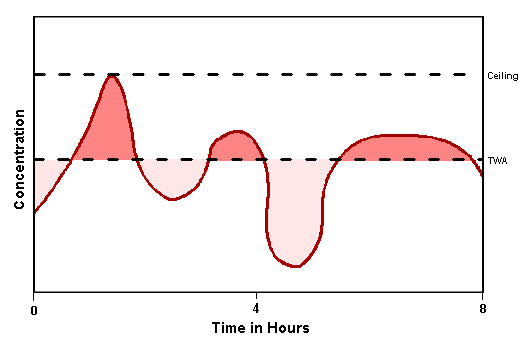

There are several ways to determine if there is a risk of heat stress and heat stroke in the workplace. The values can be determined using a heat index and TLV (Threshold Limit Values). These are guidelines designed for use by industrial hygienists in making decisions regarding safe levels of exposure to various chemical substances and physical agents found in the workplace.

|

Heat Index |

Risk level |

Protective Measures |

|

Less than 91º |

Low, but with caution |

Basic heat safety is employed |

|

91º-103º |

Moderate |

Employ precautions and raise awareness |

|

103º-115º |

High |

Employ protective measures to protect welders |

|

More than 115º |

Very high to extreme |

Higher protective measures or even rescheduling work |

Another, and for many reputable organizations, including OSHA, better way to determine risk factors is the WBGT monitor. Heat index only utilizes air temperature and moisture to give recommendations, while WBGT also includes radiant heat and wind. If you add the clothing adjustment factors, you get the effective WBGT, and this is the simplified heat risk table provided by OSHA:

|

Effective WBGT |

Risk for Unacclimatized Welders |

Risk for Acclimatized Welders |

|

Below 70º |

Low risk |

Low risk |

|

70-77º |

Energy-consuming work possibly risky |

Low risk |

|

Above 77º |

High risk during energy consuming work |

Energy-consuming work possibly risky |

Tips On How To Prevent Heat Stoke While Welding

Now that you are fully aware of why heat stress occurs and how serious extended heat exposure can be for a welder, it is time to talk about prevention. While the best way to prevent any risk during the welding job is to avoid working in heat, sometimes that's impossible. Therefore, by following our tips on preventing heat stress when welding, you can minimize the risks.

1. Take Appropriate Breaks

During hot weather, welders need to take appropriate breaks. As the environmental temperature rises, you cannot afford to raise further your metabolic temperature. During breaks, you can remove your PPE and helmet to let your body cool properly.

For supervisors, estimating each worker's workload is important. If possible, welding should be scheduled in the cooler part of the day. When in doubt about a worker's physical activity level, assume a higher workload or consult a qualified occupational safety and health professional.

While rest cycles can reduce overall productivity, keep in mind that worker safety is more important. Welders will perform tasks and achieve critical weld quality only if they are working in the proper work environment. Air conditioning can also help, but when working in the field, extra precautions should be employed.

Personal Protective Equipment (PPE) For Welders

Source: https://www.safetypostershop.com/category/welding-safety-posters/

2. Stay Hydrated

Staying hydrated is crucial when welding in hot weather. As noted, the body regulates the temperature by sweat. When you sweat, you lose important electrolytes, including sodium and potassium, which help to regulate the fluid levels in your body. Therefore, dehydration can cause several heat-related illnesses, such as syncope, exhaustion, and eventually stroke.

To avoid most heat-related illnesses when welding in hot conditions, you will need frequent hydration breaks. Keep in mind that besides water, you can opt for electrolyte-rich drinks to keep your fluid levels on average and, therefore, body cooling functional. Proper hydration is crucial for keeping welders cool and functional during the welding in the summer.

Source: https://www.girlsgonestrong.com/blog/articles/water-hydration/

3. Use Light Equipment

Welders don’t have the luxury of removing layers as temperatures rise. Gloves, jackets, sleeves, helmets, and other protective gear is most often required while performing their job. PPE for welders is usually bulky, but comfort is a top priority when it comes to welding in the heat. High-amp applications require thicker leather gloves and jackets, but during the summer, lightweight breathable materials help naturally cool the body by letting air hit the skin more directly.

Luckily, recent advances in materials have allowed manufacturers to eliminate weight and improve breathability in welding protective products. Therefore, use sweat-absorption clothing whenever possible. Letting air hit the skin more directly reduces the risk of overheating and sweating. You can choose to wear welding sleeves and a welding apron to shield yourself while you work.

AP-1166 Heat Resistant Welding Gloves

4. Use Cooling Gear

To prevent heat issues during welding, some manufacturers introduced cooling equipment, such as cooling bands and belts. Lightweight commercial cooling bands and cooling belts will keep the head and core cool by routing cool air where it's needed most, at the welder's face. Cooling gear utilizes constant airflow over the welder’s head and face.

If you are spending hours in the sun under the welding helmet, you should consider a cooling band. The main difference with the CoolBelt is the location of the fan, which is secured on the welder's lower back. Air flows upward through a piece of tubing that fits into the welder’s helmet. This cooling fan provides consistent airflow to reduce the temperature under the hood up to 17°F.

5. Consider Welding Umbrella

If you are a field worker, such as a pipeline welder, working in the sun is not something new for you. However, during a hot summer day, you should consider protection in the form of welding umbrellas. Welding umbrellas are protective pieces of equipment made of durable, fire-resistant materials. As a result, the umbrella will prevent direct UVA/UVB sun exposure. Staying in the shade significantly reduces the direct and, therefore, overall heat exposure.

Additionally, since these umbrellas are specifically made for welders and from fire-resistant materials, you don't have to worry about sparks causing a fire. Therefore, you can weld safely and away from direct sun exposure in the field.

Source: https://shop.pipelinerscloud.com/pages/the-pipeliners-cloud-welding-umbrella

6. Acclimatization

If you are changing your job or moving to a new location, take your time to acclimate. Acclimatization is the time needed for physiological adaptation to extreme temperature changes. This is extremely important if you are moving from colder to the parts affected by heat weave.

Photo by @ underground_metal_works and ironworkersnyc40361

According to experts, it will take an average individual about 1 to 2 weeks to adapt to extreme hot temperatures. After that period, you can achieve a steady state equilibrium between body heat production and heat loss to the environment. However, keep in mind that you can lose the power of acclimatization quicker than you can gain it.

Photo by @g.r.w._outlaws and commercial.dive

7. Take Care Of Your Welding Equipment

Keep in mind that your welding equipment is also affected by heat. You probably know what the duty cycle of your machine represents, but not many are aware that the duty cycle is measured at an external environment of 104°F. When doing an outdoor project, direct and intense sunlight can heat up the welding machine well over this value.

As the environmental heat rises, the duty cycle of the machine and your TIG torch or MIG gun drop. Just like the body, your welder struggles to cool down, and thermal overload kicks in. Industrial-grade machines are more resistant to extreme weather, but your hobby welder can easily get damaged if you don't pay attention to the heat.

Conclusion

High heat is not strange to welders, but as the environmental heat rises, the risks of heat-related illnesses rise. From heat rash, cramps, and fainting, the heat can eventually cause heat stroke, a severe condition that can have fatal consequences. Due to the nature of the job, welders are particularly in danger of heat stroke.

To reduce risk and keep your safe during the welding, you should follow several tips. First, try to make occasional breaks to let your body cool. During summer, use light and sweat-absorbant equipment that can allow your body to breathe. If unavoidable, consider cooling bands and other cooling equipment.

🧐How To Prevent Heat Stroke While Welding - FAQ

1. What Causes Heat Stress When Welding?

While you might think that high temperature is the leading cause of heat stress when welding, there are many factors that have a role in creating an occupational heat stress risk for welders. Besides the temperature, as a welder, you should be aware of the following:

- Environmental conditions

- Level of physical activities

- Use of clothing or protective gear

- Individual/personal risk factors.

2. How to determine the risks when welding in the summer?

There are several ways to determine if there is a risk of heat stress and heat stroke in the workplace. The values can be determined using a heat index and TLV (Threshold Limit Values). These are guidelines designed for use by industrial hygienists in making decisions regarding safe levels of exposure to various chemical substances and physical agents found in the workplace.

|

Heat Index |

Risk level |

Protective Measures |

|

Less than 91º |

Low, but with caution |

Basic heat safety is employed |

|

91º-103º |

Moderate |

Employ precautions and raise awareness |

|

103º-115º |

High |

Employ protective measures to protect welders |

|

More than 115º |

Very high to extreme |

Higher protective measures or even rescheduling work |

3. Tips On How To Prevent Heat Stoke While Welding

- Take Appropriate Breaks

- Stay Hydrated

- Use Light Equipment

- Use Cooling Gear

- Consider Welding Umbrella

- Acclimatization

- Take Care Of Your Welding Equipment

Leave a comment