How To Weld Titanium

Ah, Titanium. The holy grail of metals. Light, corrosion resistant, and extremely strong. But none of these exceptional characteristics are worthwhile if it's difficult to join it. Almost everything around us is a welding product, one way or another, so any metal we wish to use must have good weldability. Fortunately, titanium is one such metal.

This article will teach you how to weld titanium like a pro. Strap up because we are about to take you on a learning adventure that can have you repairing expensive titanium parts for aerospace, marine, and other high-value industries.

Welding titanium is not difficult if you know what you are doing. However, there are multiple crucial areas where you could fall short and mess up a costly part. Therefore, we highly suggest researching this material and gaining as much experience as possible before you try to weld something expensive like a Lamborghini exhaust pipe.

Source: https://www.lamborghini-talk.com/threads/lamborghini-aventador-svj-titanium-exhaust-system.226504/

Titanium Properties And Welding Challenges

Titanium is almost 50% lighter than stainless steel but more than two times stronger. So, it has a nearly four times better strength-to-weight ratio. However, titanium has a melting point at about 1670°C (3035°F), while stainless melts at about 1450°C (2642°F). Therefore, you may need some more amps to get the puddle going.

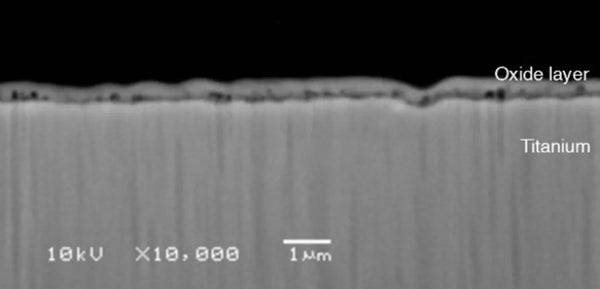

Like aluminum and many other non-ferrous metals, titanium has a strong affinity for oxygen. When left at room temperature, titanium will create a thin titanium oxide film on its surface. This oxide layer is a positive factor because it prevents additional reactivity, but it makes welding challenging. Titanium oxidizes rapidly when heated above 650°C (1200°F). So, it's imperative to provide exceptional shielding gas coverage for maximum weld quality.

Source: https://www.hellonaturalliving.com/titanium-dioxide-is-it-safe-or-should-you-avoid-it/

Titanium is highly susceptible to contamination. If oxygen, hydrogen, nitrogen, carbon, or other elements are introduced to the weld, titanium will become brittle. However, different grades of commercially available titanium contain varying amounts of impurities as a result of the industrial processing of titanium. Still, you don't want to add additional impurities because that will weaken the weld.

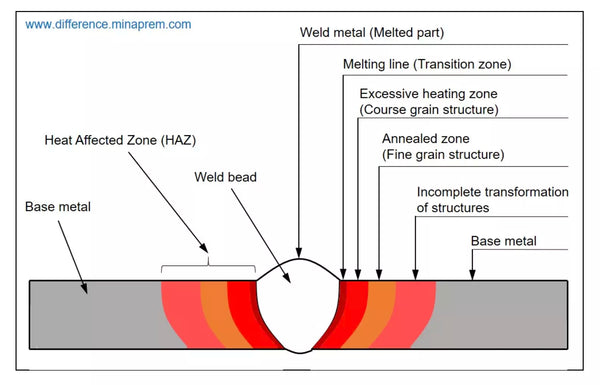

The increased presence of contaminants in the weld pool reduces the titanium's ductility and may cause weld metal cracking. For example, if the oxygen is picked up at a high level, the weld can experience transverse cracking along the weld face or heat affected zone (HAZ).

Source: https://www.difference.minaprem.com/joining/difference-between-weld-metal-and-heat-affected-zone-haz/

Recognizing Severe Titanium Oxidation

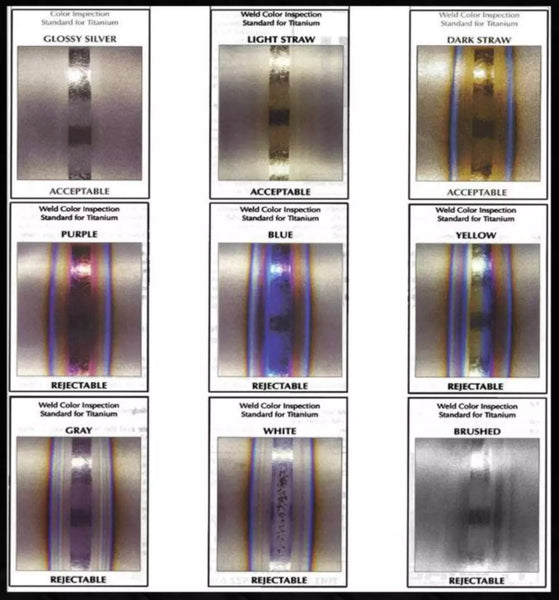

Like stainless steel, titanium will tell you if it became too oxidized during the welding process. However, titanium has different rules than stainless steel. The weld and HAZ surfaces will change colors ranging from silver, straw-yellow, blue, and white. These colors indicate the level of titanium oxides that were formed as a result of welding.

Here is a brief color guide to recognizing the titanium weld quality:

|

Silver |

Straw Color |

Blue |

White |

|

Low oxides |

Acceptable oxides |

Weld is likely too oxidated |

Weld is not acceptable |

Now you may be asking yourself: "Wait a minute... Silver is great, but white is bad?"

That's right. Unlike stainless steel, titanium surface oxides don't turn black at the final, unacceptable weld oxide stage. Instead, titanium oxide buildup that's excessively white is a clear sign that the weld picked up too many oxides and is likely weak and unreliable.

Photo by @nqnweld

However, here is an important note:

Just because the weld is clear from surface oxide, doesn't mean that the weld is safe for critical applications! This is just a simple visual way to evaluate the weld quality. But, titanium can easily pick up oxygen and other contaminants deep within the weld metal. So, you shouldn't rely on visual confirmation alone.

Source: https://weldinganswers.com/how-to-weld-titanium/

Important Safety Notes on Titanium

Titanium dust is flammable and can spontaneously combust! So, ensure that you don't have any flammable items in the nearby vicinity of the work area before you grind or otherwise shape titanium joints. In addition, sweep the titanium dust from the work area before welding to prevent any sparks from igniting the titanium dust and shavings.

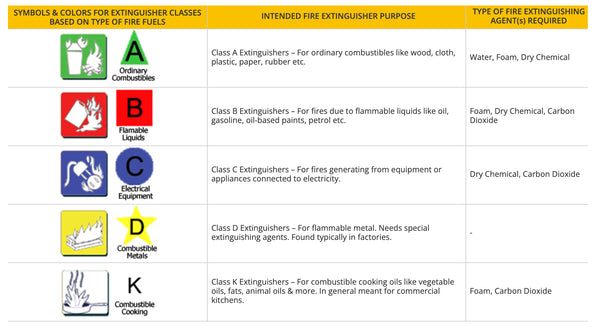

Don't use water to fight titanium-induced flames because it may explode! Instead, ensure that you have a working Class D fire extinguisher. They are designed for fighting fires from combustible metals like sodium, magnesium, and of course, titanium.

Source: https://www.mysafetysign.com/Types-of-Fire-Extinguishers

How To Prepare Titanium For Welding

Preparing the titanium joint for welding is crucial for a successful weld! You must clean the metal perfectly and shape the joint without smearing the material.

Wear nitrile gloves to prevent moisture and oils from your skin from contaminating the weld joint. Yes, for absolute joint quality, titanium requires avoiding skin-to-joint contact. You can never be too clean with this material.

Use acetone or methyl ethyl ketone and a brand new, clean, lint-free cloth to wipe the titanium joint clean from any oils, grease, dust, and other hydrocarbons.

Source: https://www.youtube.com/watch?v=Vy6qk7aZy_4

DON'T use Chlorinated Fluoro Carbon (CFC) or other chlorides to clean titanium. They can lead to stress-corrosion cracking after the welded piece is heated above 430°C (800°F) during welding.

Source: https://en.wikipedia.org/wiki/Stress_corrosion_cracking

Next, you need to remove the titanium oxide layer that formed naturally on the surface. You can use a file or a stainless steel wire brush if it's a small joint, or use a flap wheel or grinding wheel for titanium. However, if you use a grinder, avoid concentrating too much pressure in one area and grind slowly to avoid localized heat buildup. Wipe clean the joint again after grinding off the titanium oxide.

If using carbide burrs, stainless brushes, and other tools, make sure they are dedicated to titanium only. Inclusions from carbon steel and other metals can contaminate titanium and weaken the weld.

Clean the titanium filler metal wire from oxides as well. We'll get to wire selection soon, but just keep in mind that wire can also oxidize and introduce titanium oxide in the weld pool. It's also recommended to clip the end of the filler wire just before welding to expose the pure titanium underneath at the beginning of the weld.

Purging The Weld

Since titanium is so reactive with oxygen and susceptible to contamination from hydrogen and nitrogen, you must purge the underside of the weld with a non-reactive gas like argon. While the shielding gas from MIG or TIG welding process will protect the weld from above, the back side of the weld will get oxidated, lose corrosion resistance, and become brittle unless you purge the air and replace it with argon. Purging the weld is especially important when joining titanium pipes.

You can make a DIY purging solution by plugging both sides of the pipe shut with tape. Then, poke a hole in one end and stick an argon gas hose through it to force the air outside and replace the inside atmosphere with argon. Of course, there are commercial products for professional pipe purging, but you may be able to get a good purge with a little bit of a DIY.

Source: https://www.youtube.com/watch?v=Vy6qk7aZy_4

Here is a purging pro tip for you: If you have multiple joints on a titanium pipe system, like a motorcycle or sports car exhaust pipe system, tape the joints at the bottom and keep those higher joints loose. Argon is heavier than air, so you want to push the argon through the system starting from the lowest point of the pipe system all the way to the highest point.

Welding Process Selection

We highly recommend sticking to Gas Tungsten Arc Welding, otherwise known as TIG, to weld titanium. The TIG welding process provides excellent precision and lets you carefully direct the shielding gas using a wide cup and gas lens setup.

You can also MIG weld titanium, but not many people do it. However, you are less likely to achieve the same weld quality as with the TIG welding process. The MIG welding process produces too much heat and spatter for titanium and can lead to excessive contamination by impurities in the arc atmosphere. Since the molten titanium filler metal droplets are tiny when MIG welding and they are flying through the arc down the joint, there is a higher chance for them to oxidize and get contaminated at such high heats and low material volumes.

The TIG welding process is universally accepted as the best way to join titanium. Fluxed welding and oxy-fuel welding are NOT recommended to weld titanium or titanium alloys.

Source: https://industrialmetalservice.com/resources/welding-titanium-the-challenges-of-proper-shielding/

TIG Welding Titanium

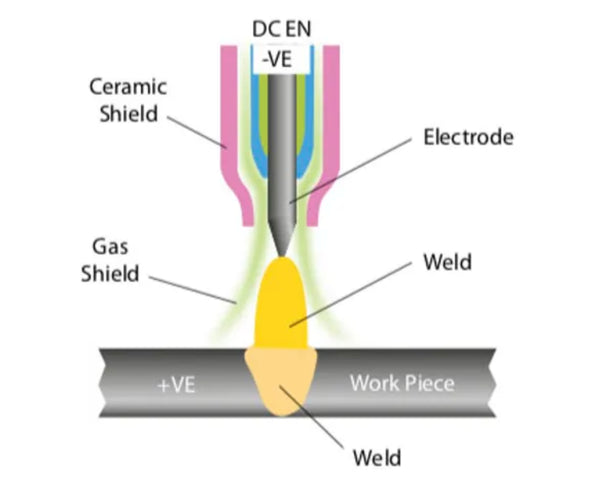

The tungsten inert gas welding process uses a non-consumable tungsten electrode to transfer an electrical and inert shielding gas to protect the weld puddle from atmospheric contamination.

You need to use Direct Current Electrode Negative (DCEN) TIG welding polarity to weld titanium. While it's necessary to use AC TIG to weld aluminum or magnesium, titanium doesn't require AC TIG output.

Source: https://www.jasic.co.uk/post/what-are-the-differences-between-tig-dc-and-tig-ac

However, you don't want to use just any plain DC TIG welder, either. Your TIG machine should be equipped with a high-frequency arc start to prevent the tungsten electrode from contaminating the titanium. In addition, pulsed TIG welding is a welcome feature to prevent excessive heat input and improve weld penetration. A welder like the YesWelder YWT-200DC supports all of the beneficial features, including the foot pedal support, but stays at an economical price because it's not burdened by AC TIG.

YesWelder YWT-200DC Lift TIG Spot TIG Welder

When TIG welding titanium, you'll notice that its weld pool behaves quite similarly to stainless steel or nickel alloys. So, if you've had previous experiences with those materials, you won't have many issues.

However, titanium requires extra shielding gas protection. Therefore, you need to ensure no wind drafts in the area where you are welding. In addition, it's probably better to use gas lens for titanium because of a more consistent shielding gas coverage. You should also use a large nozzle/cup to prevent the heated parts from coming in contact with the air. A larger TIG cup will provide a broader shielding gas coverage and better protect the sensitive, heated titanium.

Source: https://www.youtube.com/watch?v=UolR5eiVKQQ

TIG welding titanium works best when performed in the flat position. Vertical or out of position welding can negatively impact the shielding gas coverage, which can have devastating consequences for titanium.

Shielding Gas Selection

To TIG weld titanium, we recommend using 100% argon. But you can add helium to the mix as well. Still, helium is unnecessary for titanium, and it's more expensive than argon. So, there aren't many reasons to stray from welders' favorite — straight argon shielding gas.

It's extremely important to get a high quality argon shielding gas tank. The higher the purity of the argon tank, the better the weld will be. Many welders experience weld discoloration (oxidation) when welding titanium and can't seem to find the culprit. If the gas tank has air and moisture inside, you can experience weld oxides. The only solution to this problem is to get a better quality argon tank.

Source: https://www.youtube.com/watch?v=x7_leMg1G9A

Typically, argon shielding gas for welding aluminum should have at least 99.995 percent purity with less than 20 parts per million (PPM) of oxygen and a dew point greater than -76 degrees F. Some applications even require a 99.999 percent argon purity.

Tungsten Electrode Selection

Most welders use thoriated and lanthanated tungsten electrodes to weld titanium. However, you can also use ceriated tungsten if welding thin sections at low amps — ceriated, grey tungsten works well for low amps applications across the board.

Grind your tungsten electrode sharply to a point, but be careful not to touch the titanium at any moment. Pointy tungsten can erode and contaminate the weld pool and cause embrittlement. Your tungsten electrode stickout should be as limited as possible, but don't compromise your weld pool visibility either.

Filler Metal Selection

You should strive to match the filler metal alloy to the titanium alloy you are welding. To weld commercially pure titanium, use unalloyed titanium filler metal because it can tolerate atmospheric contamination well, without a significant ductility loss of the weld metal. You can also use unalloyed titanium filler wire to weld some specialty titanium alloys to improve ductility at some loss of strength, but this requires a very dedicated approach. Consult the engineer if welding specialty alloys like alpha base titanium.

American Welding Society specifies filler metals for titanium in the AWS A5.16/A5.16M:2007 Specification for titanium and titanium-alloy welding electrodes and rods.

Some of the most common titanium filler wires are ERTi-2, ERTi-3, and ERTi-4. But there are many other titanium filler metals, and each has a slightly different chemical composition suitable for the titanium alloy you are welding.

Post Weld Shielding Gas Flow

It's crucial to maintain a shielding gas flow post-welding until the weld has cooled below 430°C (800°F) to prevent rapid weld oxidation. You can try making a short weld on a scrap piece without providing a post-shielding gas flow and see just how quickly the weld will start to oxidize.

Use post-welding gas flow of at least the 20s. Sometimes you may even require more, depending on the titanium's thickness. If your welder doesn't support a higher setting than the 20s for post flow, lightly press on your TIG foot pedal to initiate a small arc for just a fraction of a second as you are holding the torch over the completed weld and the welder will release another 20s of gas.

Sometimes it's also necessary to use a trailing shielding gas fixture. This allows you to shield the weld bead as you move along the joint. However, this is not always required for manual welding. It's usually used for fast, automated welding of titanium.

Conclusion

Titanium is not a complex material to weld if you nail the basics right. If you walk away with anything from this guide, let it be the need for maximum cleanliness and shielding gas protection from the atmosphere. Just nailing these two would make you a ten times better titanium welder than a rookie who hasn't welded this material before.

🧐How To Weld Titanium - FAQ

How to recognize severe titanium oxidation?

The weld and HAZ surfaces will change colors ranging from silver, straw-yellow, blue, and white. These colors indicate the level of titanium oxides that were formed as a result of welding.

What is titanium welding process selection?

We highly recommend sticking to Gas Tungsten Arc Welding, otherwise known as TIG, to weld titanium. The TIG welding process provides excellent precision and lets you carefully direct the shielding gas using a wide cup and gas lens setup.

What is titanium shielding gas selection?

To TIG weld titanium, we recommend using 100% argon. It's extremely important to get a high quality argon shielding gas tank. The higher the purity of the argon tank, the better the weld will be.

👏 You may be interested in the following:

Leave a comment