Types of Welding Metals

Welding is one of the most complex and widely used metal joining processes globally, as it provides the ability to join various metals with precision and strength. Today, there are 94 metals on the periodic table, but some are used more or less in welding.

In this article, we unravel the most popular types of welding metals, dissecting the various metals artisans and engineers use, from delicate alloys to robust steel structures. We will navigate through the characteristics, applications, and unique challenges posed by different welding metals.

Types Of Metals Used In Industry

According to the Royal Society of Chemistry, there are 94 metals on the periodic table, accounting for 75% of all elements in the table. Each metal has unique properties that give it a different melting point, thermal conductivity, density, and malleability; some are lightweight but strong, and some are corrosion-resistant.

Regardless of the properties, all metals can be grouped by the presence of iron. Therefore, we are seeing three different types of welding metals:

- Ferrous metals

- Non-ferrous metals

- Metal Alloys

Ferrous metals contain iron, while non-ferrous metals contain no iron. Finally, alloys are complex metals that contain multiple metals and other elements that provide unique properties that can be suitable for various applications.

Most Common Welding Metals

Each metal has different strength, durability, aesthetics, temperature tolerance, thermal and electrical conductivity, and cost. While these give the metal favorable properties in applications that require strength or corrosion resistance, they can affect its weldability. That's why some metals are used more in welding, while some use oxyacetylene, bolting, or riveting as an alternative.

Riveting refers to rivet connection.

Source: https://www.hlc-metalparts.com/

The most common metals used in welding are:

- Steel

- Stainless steel

- Aluminum and aluminum alloys

- Copper and copper alloys

- Nickel and nickel alloys

- Magnesium and magnesium alloys

- Cast iron

Each of these has unique properties that require different types of welding methods and a different approach in terms of weld preparation, heat treatment, heat input, and post-weld processing. So let's find out more.

Steel Welding Metal

Steel is the most common metal in the modern world. It is a ferrous alloy typically made of 99% iron and 1% carbon, with small amounts of other elements added to enhance its properties. Mixing iron, carbon, and other alloying elements creates a strong, fracture-resistant metal.

Source: https://worldsteel.org/about-steel/about-steel/

Steel has a high melting point, making it suitable for welding processes involving high temperatures, such as Stick or Arc welding and oxy-acetylene welding. Steel has good thermal conductivity, allowing for efficient heat transfer during welding. This property is crucial for achieving uniform and effective welded joint fusion.

Steel exhibits a balanced combination of ductility and toughness, making it well-suited for welding applications where deformation and impact resistance are essential. This property comes from a low-carbon content, which makes it easy to weld which is so widely used across the globe. Also, steel is relatively cheap, which once again makes it highly used.

Steel Alloys

Steel alloys are composed of iron and carbon, with the addition of other elements in varying proportions to achieve specific desired properties. The alloying elements can enhance characteristics such as strength, hardness, corrosion resistance, and machinability. Primary types of steel alloys are carbon steel, stainless steel, and alloyed steel.

Carbon steel is the most basic steel alloy, usually made solely of carbon and iron. They can be further specified as low-carbon steel, medium-carbon steel, and high-carbon steel. As the carbon content increases, the steel is harder and more suitable for high wear and tear applications, but it is more challenging to weld without cracks or breaking.

Stainless steel contains iron, chromium, nickel, and other elements. Stainless steel is known for its corrosion resistance and is often used in applications where resistance to rust and staining is critical. Common types include austenitic, ferritic, and martensitic stainless steels.

Alloyed steel is complex and contains additional alloying elements, such as manganese, silicon, copper, nickel, chromium, and molybdenum, to improve specific properties. This makes the steel customizable for a project, but it can make it more challenging to weld.

Welding Steel

Low carbon steel or mild steel is one of the most accessible metals to weld, as it has a good balance between ductility and strength, with moderate thermal characteristics. As a result, you can weld it with any of the most popular arc welding processes, such as Gas Metal Arc Welding (MIG welding), Shielded Metal Arc Welding (Stick welding/Manual Metal Arc Welding), Gas Tungsten Arc Welding Process (TIG welding) or Flux Core Wire.

Since steel has favorable thermal properties, you can weld it without preheating or any specific weld preparation and post-heating. You don't need any fancy welding techniques, so you can easily weld it as a beginner and with a hobby welding machine. The primary drawback of carbon steel is a lack of resistance to corrosion and a somewhat low strength-to-weight ratio, which is why critical applications turned to other metals.

Stainless Steel Welding Metal

Stainless steel is a corrosion-resistant alloy of iron, chromium, and other elements such as nickel, molybdenum, and manganese. The addition of chromium forms a protective oxide layer on the surface of the steel, giving it its corrosion-resistant properties.

The hallmark property of stainless steel is its corrosion resistance and combined with durability, strength, and resistance to rust and staining, it is widely used in various industries, including construction, automotive, aerospace, and food processing.

Stainless Steel Alloys

There are thousands of stainless steel alloys, each designed to meet specific performance requirements for various applications. Each formulation of stainless steel alloy has its unique properties for tensile strength, melting point, oxidation resistance, and corrosion resistance. However, there are five main categories of stainless steel alloys:

- Austenitic Stainless Steels: These alloys are among the most frequently used types of stainless steel. They tend to have a high chromium content compared to other steel alloys, giving them a higher resistance to corrosion. They also tend to be non-magnetic.

- Ferritic Stainless Steels: These are the second most common form of stainless steel. As the name implies, ferritic stainless steel is magnetic. These alloys can be hardened through cold working. They also tend to be less expensive because of their reduced nickel content.

- Martensitic Stainless Steels: The least common category of stainless steel alloy since their corrosion resistance tends to be lower than ferritic or austenitic alloys. Still, martensitic stainless steel alloys are harder, which makes them ideal for applications requiring extraordinarily high tensile strength.

- Duplex (Ferritic-Austenitic) Stainless Steels are made of half austenite and half delta-ferrite, which provides better corrosion resistance, especially against chloride pitting, and higher tensile strength than standard austenitic stainless steels. They are used widely in the oil and gas industry for pipework systems or as pipelines and pressure vessels in the petrochemical industry.

- Precipitation-Hardening (PH) Stainless Steels: This category comprises durable, corrosion-resistant alloys with exceptional strength. They can be treated to yield strengths three to four times that of standard austenitic stainless steel.

Precipitation-Hardening (PH) Stainless Steels

Source: https://www.ulbrich.com/blog/precipitation-hardening-stainless-steel-alloys-guide/

Welding Stainless Steel

Stainless steel is generally weldable, as it can be welded with TIG, Stick, or MIG welding stainless steel, but the process can be more challenging compared to welding carbon steel. Unique properties, including high thermal conductivity and low thermal expansion, require careful consideration during welding to avoid issues such as distortion and cracking. If you apply excess heat, stainless steel can warp or even distort as it cools.

Proper preparation is crucial when welding stainless steel. Contaminants such as grease and oxides must be removed, and the use of the correct shielding gas (typically argon or a mixture with helium) is essential. Post-weld treatments, such as passivation, may be necessary to restore the corrosion resistance of the welded area.

Choosing the right filler metal is crucial for successful stainless steel welding. Since there are over a thousand alloys, beginners can have a hard time choosing the suitable filler material for the given alloy, which heat control can present a unique challenge for beginners.

Aluminum Welding Metal

Aluminum is a lightweight and highly versatile metal known for its excellent corrosion resistance, thermal conductivity, and low density. Aluminum offers a one-two punch; it is lightweight without sacrificing strength. In fact, some aluminum alloys are as strong as structural steel.

Aluminum’s versatility goes beyond its weight and strength. It’s easily workable in any form and can take on an impressive variety of surface finishes. Under most service conditions, aluminum shows high resistance to corrosion. Advantageous properties make aluminum widely used in various industries, including aerospace, automotive, construction, and electronics.

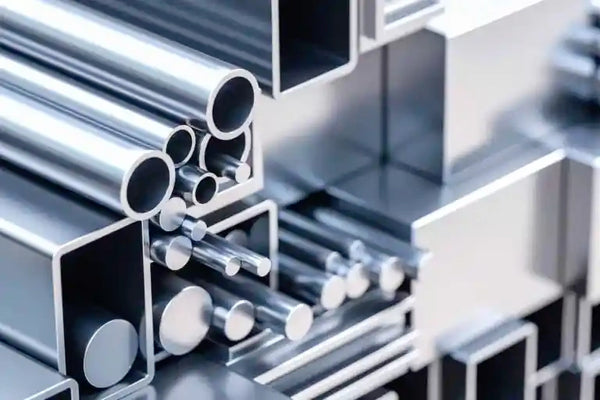

Aluminum Alloys

Remember that pure aluminum is soft and demonstrates only moderate strength, which is why much of aluminum’s versatility is owed to specific alloying elements. Aluminum alloys usually have a 4-digit designation. The first digit designates purity or alloy type. The second digit indicates modifications of the alloy. Similar to steel, there are various alloys, and they can be broken down into three categories: wrought heat treatable, wrought non-heat treatable, and casting alloys.

The most popular aluminum grades for welders are 3003, 5052, 5083, 5454, 6061, and 6063. These are all generally weldable alloys with moderate-to-high strength and excellent weldability. They provide high weld efficiency and very high joint strength.

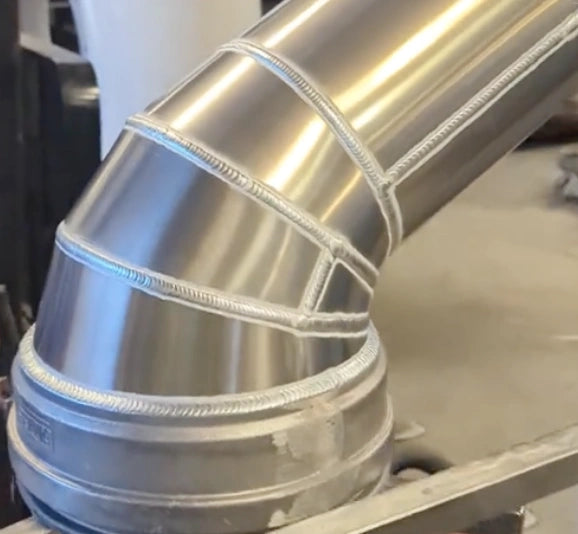

TIG welding on aluminum 5052

Source: https://www.youtube.com/watch?v=WHuUt7fHHtM

Welding Aluminum

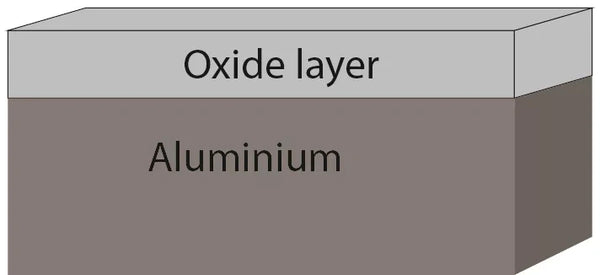

Aluminum is among the most challenging metals to weld due to its oxide layer and thermal characteristics. When the aluminum surface is exposed to air, it reacts and creates an oxide layer that provides corrosion resistance. However, this layer has a three times higher melting temperature than aluminum, so burning through it can quickly burn through the rest of the metal.

Additionally, aluminum has a much higher thermal conductivity than steel, so you need to apply more heat energy to the weld. However, high heat can easily cause burn-through or distortion and warping, so you need excellent heat control.

That's why TIG welding is the most popular aluminum welding method. It provides just the right heat control to ensure proper penetration without the risk of overheating or burning through the base pieces. Additionally, you can MIG weld aluminum, which is easier, but you will need specialized equipment for it. Similar to stainless steel, you will need good weld preparation, including preheating and removing the oxide layer.

Copper Welding Metal

Copper is a ductile and malleable metal with excellent electrical and thermal conductivity. It has a reddish-brown color and is often used in various industries for its conductivity, corrosion resistance, and versatility.

Copper is renowned for its exceptional electrical conductivity, making it a preferred material for electrical components, wiring, and conductors. Copper also exhibits excellent thermal conductivity, making it suitable for applications where heat dissipation is crucial. This property is beneficial in the production of heat exchangers and specific electronic components.

Copper Alloys

There are multiple types of copper alloys:

- Nickel silver (copper-nickel-zinc)

- Copper-nickel

- Copper-silicon or Silicon bronze ()

- Aluminum bronze (copper-aluminum alloy)

- Copper-tin

- Copper-zinc or Brass

- High copper alloys (up to 5% alloy)

Each shows different characteristics, so welding copper is challenging because there is a vast array of alloys, and it may require special attention, heat treatment, or specific filler material.

Welding Copper Alloys

Copper is highly ductile and malleable, allowing it to be easily drawn into wires or shaped into various forms. It is also considered weldable, and various welding processes can be employed based on the specific application. However, the challenges of welding copper emerge from its thermal characteristics and the fact that each alloy presents different characteristics.

Due to incredibly high thermal conductivity, the heat will rapidly dissipate through the welded part and away from the joint, which can result in a lack of penetration. Due to the high coefficient of thermal expansion, copper can warp, distort, or crack when exposed to high heat or once it cools down quickly, so it requires preheating and posheating.

However, when all things are taken into account, copper can be brazed, soldered, or welded by MIG welding and TIG welding or resistance welding methods, such as spot welding or seam welding.

TIG Welding Copper

Source: https://www.youtube.com/watch?v=3pV6c0TkbEs

Nickel And Nickel Alloy Welding Metal

Nickel is a versatile metallic element known for its corrosion resistance, high-temperature strength, and excellent electrical conductivity. It is often alloyed with other metals to enhance specific properties. Nickel and its alloys find extensive use in various industries, including aerospace, chemical processing, electronics, and power generation.

Types of nickel alloys are identified by welding processes and techniques that can be used to fabricate nickel alloy components without affecting their corrosion or mechanical properties or introducing flaws in the weld. As a result, we see

- Solid solution alloys are pure nickel, Ni-Cu alloys, and the more straightforward Fe-Ni-Cr alloys,

- Precipitation-hardening alloys such as Ni-Cu-Al-Ti, Ni-Cr-Al-Ti, and Ni-Cr-Fe-Nb-Al-Ti.

Welding Nickel Alloys

Most nickel alloy welding can be fusion welded by gas-shielded processes like TIG or MIG. MMA is frequently used in the flux processes, but the SAW process is restricted to solid solution alloys and is less widely used.

Solid solution alloys are typically welded in the annealed condition, and precipitation-hardened alloys in the solution-treated condition. Preheating is unnecessary unless there is a risk of porosity from moisture condensation. Post-weld heat treatment is not usually needed.

Magnesium and Magnesium Alloys

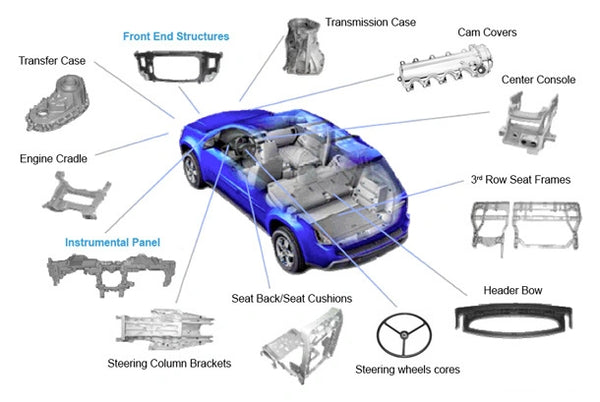

Magnesium is a lightweight, silvery-white metal known for its low density, high strength-to-weight ratio, and excellent machinability. It is often used in applications where weight reduction is critical, such as in the aerospace and automotive industries.

Despite its low density, magnesium exhibits high strength, providing a favorable strength-to-weight ratio. Magnesium alloys are known for their excellent machinability, allowing for precision machining and intricate part production.

Magnesium is often combined with other materials to increase its strength and suitability for various applications. Some commonly used alloying elements include zinc, aluminum, manganese, zirconium, and rare earth metals. The specification for these magnesium alloys consists of one or two letters indicating the specific alloying elements, followed by the percentage of each element in the alloy.

Welding Magnesium Alloys

Magnesium and its alloys are generally weldable using various techniques, including Gas Tungsten Arc Welding (GTAW or TIG) and Metal Inert Gas (GMAW or MIG) welding. Advanced applications often use modern processes such as plasma arc welding, atomic hydrogen welding, electron beam welding, etc.

However, there are unique challenges with magnesium alloy welding since magnesium is highly reactive, especially at elevated temperatures. This reactivity increases the risk of oxidation during welding. Thermal properties such as low melting point and high thermal conductivity require good heat control and proper preparation, similar to aluminum welding.

Cast Iron

Cast iron is a ferrous alloy that contains a higher proportion of carbon than steel, typically between 2% and 4%. It is made from pig iron, which is the product of melting iron ore in a blast furnace through a process of casting.

Exceptionally high carbon content makes cast iron exceptionally strong, which is suitable for applications with high wear resistance, but it makes it exceptionally hard to weld. As a result, components are used in engine blocks, exhaust manifolds, pipes, and other structures.

Different types of cast iron exist, including gray iron, white iron, and ductile iron, and each may have specific considerations when it comes to welding.

Welding Cast Iron

Cast iron welding rarely involves fusing two pieces. It is commonly used for repairs on broken parts or cracks. However, welding cast iron can be exceptionally hard without developing cracks due to high carbon content. Cracks develop once the microstructure becomes hard and cools down quickly. As a result, you will need to preheat the pieces and adopt post-heating and slow cooling, which can take up to 24 hours.

Ductile iron has a more ductile and malleable microstructure due to adding small amounts of magnesium or cerium. Welding ductile iron is generally more forgiving than other types of cast iron. However, the welded joint can still crack even if you follow all the precautions and apply proper care.

Conclusion

The realm of welding metals presents a nuanced array of options. Steel, versatile and robust, anchors construction, while stainless steel ensures longevity in corrosive settings. Aluminum, prized for lightness, dominates aerospace and electronics.

Nickel's resilience to corrosion shines in aerospace and power generation. Magnesium, celebrated for low density, finds its niche in weight-sensitive applications. These welding metals, each with distinct properties, empower industries with choices tailored to specific needs, underlining the pivotal role of informed selection in successful metal fabrication.

🧐Types of Welding Metals FAQ

1. What are the most common metals used in welding?

The most common metals used in welding are:

Steel

Stainless steel

Aluminum and aluminum alloys

Copper and copper alloys

Nickel and nickel alloys

Magnesium and magnesium alloys

Cast iron

2. What are the challenges of welding stainless steel?

Welding stainless steel is challenging due to its unique properties, including high thermal conductivity and low thermal expansion. Excess heat can cause warping or distortion during cooling.

Proper preparation, including removing contaminants and using the correct shielding gas (typically argon or a helium mixture), is crucial. Post-weld treatments like passivation may be necessary for corrosion resistance. Choosing the right filler metal among over a thousand alloys can be daunting, especially for beginners, and heat control presents a unique challenge.

Leave a comment