What Is Desktop Robotic Welding?

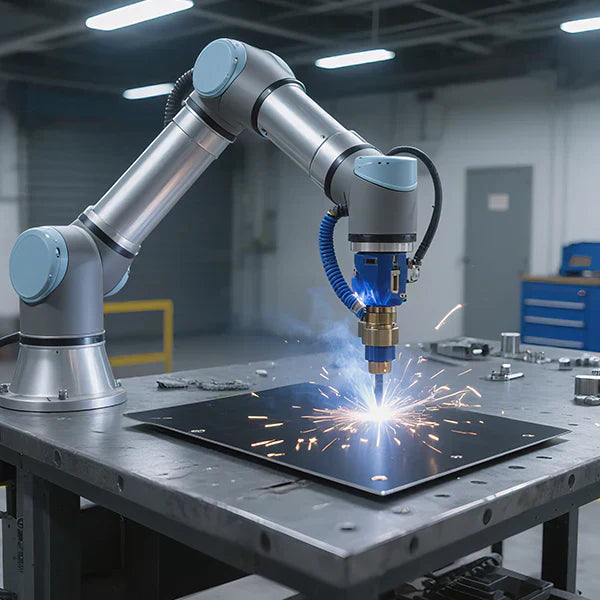

Robots and artificial intelligence are vital components of modern industry, particularly in highly automated applications. Welding is one field that works excellently with automation, so we are seeing new trends emerge.

Automated welding is not a new concept, but new trends in welding automation are emerging. Desktop robotic welding is transforming precision manufacturing by bringing automation to compact workspaces. These systems combine the accuracy of robotic arms with advanced welding technologies in a space-efficient format.

In this article, we will further explain desktop robotic welding and how this innovative, scalable solution for modern manufacturing needs, small businesses, and educational institutions is changing the industry.

Desktop Robotic Welding Process

Source: https://switchweld.com/the-complete-2025-guide-to-welding-automation/

What Is Robotic Welding?

Robotic welding combines robotics, welding, and artificial intelligence to perform automated, repetitive, and pre-programmed welds. Six-axis welding robots comprise a three-axis lower arm and a three-axis wrist. The torch is mounted at the wrist, so it works in all necessary positions for three-dimensional welding.

Six-axis Welding Robots

Source: https://www.machinedesign.com/

Operators equip robots with one of many possible welding methods. Typical examples include MIG welding, TIG welding, laser beam welding, or any modern metal joining technique that suits the needs.

The software is the brain behind the operations. Robots work thanks to pre-planned programs. Programs define the movement of the robotic arm along the welding path and manage welding parameters such as voltage, current, speed, and torch angle. Once set, robots will follow the instructions to make repetitive welds.

Artificial intelligence (AI) and smart sensors track the process in real time. Sensors detect deviations or faults and alert operators or stop the process. Although highly independent, robots still rely on operators to import the program and start welding.

The operator imports the program to start welding.

Source: https://joinerservices.io/robotic-welding/

What Can Welding Robots Do?

Welding robots are capable of performing a wide range of tasks related to metal joining with precision, speed, and consistency. Their core function is to automate the welding process, but they offer much more in terms of flexibility and productivity.

Robots can perform various welding processes, such as:

-

MIG welding: Ideal for speed, adaptability, and versatility.

-

TIG welding: Great choice for thin and delicate metals and welds that require ultimate precision and heat control

-

Stick/Arc welding: A cheap and quick method, highly valuable on thicker metals.

-

Laser welding: Produces exact, precise, and narrow welds that are ideal for delicate parts and intricate designs.

-

Plasma arc welding: Provides precision, control, and deep penetration, especially when welding thin materials.

-

Spot welding: Often used in the automotive industry to join body panels or any sheet metal.

Source: https://www.lightmetalage.com/

Welding robots provide a high level of repeatability and scalability. Once programmed, they can follow exact weld paths with multi-axis movement. This adaptability allows you to fine-tune or adjust the program to produce repetitive, accurate, and cost-effective welds.

New welding robots often provide a design and the ability to change wire automatically. Smart sensors can correct the inaccuracy of the position of individual parts. Once you finish, you can reprogram the robots to work on different parts, providing maximum versatility.

All of these result in benefits such as high speed and productivity, accuracy, quality, and safety for welding applications.

Source: https://www.robots.com/articles/arc-welding-101

Automated Welding vs Robotic Welding

Automated welding and Robotic welding are related but not identical terms. In short, all robotic welding is automated, but not all automated welding is robotic.

Automated welding refers broadly to any welding process that uses machines or control systems and minimal human intervention. It includes both mechanized and robotic systems, whether in hard automation (custom-built machinery for specific tasks) or soft automation (more flexible systems with programmable capabilities).

Source: https://www.thefabricator.com/

Robotic welding is a subset of automated welding that specifically involves programmable, multi-axis robots equipped with welding tools. Operators can reprogram robots to handle various welding tasks, and they are highly flexible.

Desktop Robotic Welding: A New Trend In Automation

When discussing automated welding, the first thing that comes to mind is a large industrial hall filled with robots, fixtures, and moving parts. However, not all automation is like that, and the perfect example is desktop robotic welding.

Traditional Automated Robotic Welding

Source: https://www.thefabricator.com/

Desktop robotic welding is a compact, automated welding system designed to perform precise welding tasks on a workbench or desktop-sized platform. These systems incorporate a small industrial robot arm with a welding tool such as TIG, MIG, or laser. They are typically designed for light-duty applications, small components, or prototyping in settings where space is limited.

Using a compact robotic system offers several advantages. Due to the smaller system and robot arm, the costs are much lower compared to traditional systems. However, it still yields higher productivity, welding safety, and quality compared to manual welding. Let’s learn more.

Compact Robotic System

Source: https://www.dobot.nu/en/applications/welding/

How Does Desktop Robotic Welding Work?

Desktop robotic welding utilizes similar equipment to all other robotic welding types. But everything is scaled down to fit a workbench or desktop-sized platform.

A small, multi-axis arm (typically 4–6 axes) provides flexibility of movement. Depending on the application, a welding head (MIG, TIG, or laser) is attached to the arm.

Control software is featured on a computer or an embedded touchscreen interface. The welding operation occurs on the compact fixture or working platform. This platform is small and often desktop-sized, hence the name desktop robotic welding.

A safety enclosure often protects the working platform. The enclosure protects operators from arc light, fumes, or moving parts, making the entire procedure highly safe.

Compact Desktop Robotic Welding Cell with Safety Enclosure

Source: https://www.motoman.com/

Programming the Robotic Desktop Welding

Although highly independent, welding robots cannot work without previous programming or manual instructions. Robots are only brute force, while software is the brain behind the operation.

Programming the path of desktop robots can be:

-

Manual teaching: The user physically guides the robot through the desired path using a teach pendant or joystick. Operators often use manual control for educational purposes or when they need manual welding with higher precision.

The user guides the robot’s path using a teach pendant or joystick.

Source: https://robodk.com/blog/program-robot-tips/

-

Offline programming: This is a more common method in which trained personnel program the welding path using CAD models or a drag-and-drop interface. Operators upload the path to the robot, which follows it with a stringent tolerance of less than a millimeter. Offline programming means you don’t have to stop production. You can develop the program independently, and then just load it when you are ready to schedule another task.

Offline Programming for Robotic Welding

Source: https://robodk.com/blog/program-robot-tips/

Besides the path, operators also include path parameters. The pathing parameters include start/stop positions, travel speed, torch angle and orientation, and dwell times at start or endpoints. However, some advanced systems use vision systems and AI to identify the weld seam and adjust the path automatically.

Welding Parameters

Setting the welding path explains the welding route, but you still need to input the welding parameters for the applications. Operators need to input voltage and current, wire feed speed (for wire welding processes), pulse frequency (for TIG or newer MIG welding), laser intensity (for laser welding), and shielding gas flow rates (for MIG or TIG).

Setting Welding Parameters Before Robotic Welding

Source: https://www.motoman.com/

Operators adjust the parameters based on metal thickness, type, joint geometry, or the selected welding process. The best part is that you can save the settings and use them later to produce repetitive welds. You can share them, but you can also tweak them if you feel something is wrong and you are not getting the best results.

Most new machines feature intelligent sensors that monitor the current, voltage, arc length, and torch position. If the values are too far off from the programmed parameters, the machine signals the error or stops altogether. These sensors provide quality assurance, which is crucial for critical, repetitive welds and operator safety.

Application of Sensing Technology

Source: https://www.sciencedirect.com/

Executing the Weld

Robotic desktop welding begins once you input the pre-programmed path and welding parameters. You place and fix the part on the working bench or desktop. Operators calibrate the robotic arm using home positions or zeroing protocols. Calibrating helps the robot find start and end positions and follow the path.

The robotic arm moves the welding torch along the programmed path with sub-millimeter precision. The welding process starts, and the installed torch or laser melts and fuses the pieces. Filler metal, if needed, is added automatically to the joint at the pre-programmed rate.

Source: https://blog.hirebotics.com/robotic-mig-welding-tips

During the weld, smart sensors and cameras monitor the weld. Sensors check for misalignment and monitor the crucial welding parameters. Some systems also feature a camera, so you can visually check the quality of the weld on the go.

The software also logs all parameters and outcomes for traceability and analysis. After the run, you can see a detailed breakdown, check what went wrong, and adjust for the next weld. Some of the latest robots feature software with AI or machine learning. Based on the logs, the software can suggest improvements for future runs to increase the performance, effectiveness, or quality of the welds.

Robotic welding software logs all parameters for traceability and analysis.

Source: https://www.hirebotics.com/

Repeatability and Flexibility

Once you get the best parameters for the job, you can save them and use them later to produce repetitive welds. Once you save the program, the system can repeat the same weld on multiple parts with consistent quality.

However, robotic desktop welding is flexible, meaning you can later load a different program, re-teach a new path, or swap out the fixture or workpiece. Some desktop systems support quick-change fixtures or modular heads for added flexibility. As a result, you can swap everything and start working on different pieces in no time.

This approach is quite the opposite of hard automation. Hard, or fixed, automation features large production lines in which machinery, robots, and industrial equipment perform singular tasks.

New welding robots support Industry 4.0 and smart manufacturing initiatives. Welding is seeing the integration of technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to enhance productivity, efficiency, and flexibility. Smart algorithms and digital interactions allow for more intelligent decision-making and customization in manufacturing operations.

New welding robots support smart manufacturing initiatives.

Source: https://vietq.vn/

Advantages of Desktop Robotic Welding

Desktop robotic welding carries industrial-grade automation to small spaces and precision tasks. This versatility results in a powerful combination of accuracy, flexibility, safety, and cost savings.

The most notable benefits of desktop robotic welding include the following:

-

Precision and consistency: Robotic arms follow programmed paths with sub-millimeter precision, ensuring identical welds every time. Precision makes it perfect for fine components where accuracy is critical. It eliminates inconsistencies caused by human error in manual welding.

-

Space efficiency: Desktop robotic welding fits on a bench or workstation. It is ideal for workshops, labs, and production areas with limited space.

Desktop robotic welding is ideal for compact workshops and labs.

Source: https://www.youtube.com/watch?v=H9UjXXONwSQ

-

Cost-efficient: Desktop systems are more compact, less complex, and significantly cheaper than industrial robotic welding systems. Accurate heat control and path following minimize material waste and rework. Additionally, you need fewer operators, which cuts the costs.

-

Flexible and versatile: Desktop robots work well with most popular arc welding, laser welding, or resistance welding methods. They can work with aluminum, steel, titanium, and other metals used in high-precision industries.

-

Improved operator safety: Most systems include shielding and fume extraction, which protect users from arc flash and fumes. Emergency stop buttons, interlocks, and fault detection also protect operators from injuries.

-

Scalability: Users can test designs and processes on a small scale before scaling up.

-

Data-driven quality control: Software captures weld data for documentation, traceability, and process optimization. Integration with Industry 4.0 systems enables predictive maintenance and performance tracking.

- User-friendly: Many systems offer drag-and-drop programming, touchscreen controls, and visual guides. You don't need high programming or robotic skills to operate machines.

Source: https://www.controleng.com/

Disadvantages of Desktop Robotic Welding

Desktop robotic welding also has certain drawbacks and limitations. You should understand them when evaluating their suitability for a specific application or production scale.

Source: https://blog.hirebotics.com/welding-robot-programming-smartphone

Notable drawbacks of robotic welding include:

-

Limited work envelope: Desktop systems are designed for compact components; they can't accommodate large assemblies or heavy-duty structures.

-

Lower power capacity: Desktop welders typically have lower current and voltage ratings, making them ineffective for welding thick metals or high-penetration applications.

-

Lower durability in industrial use: These systems are not intended for high-volume, 24/7 industrial workloads. High production can lead to quicker wear and tear compared to full-size industrial robots.

-

Higher upfront costs: Although cheaper than large-scale automated welding, robotic systems still carry higher initial investment.

-

Software compatibility: Some systems have limited customization or support fewer file types for offline programming.

Desktop robotic welding excels in precision, small-batch, and educational or prototyping contexts. However, it falls short in heavy-duty, high-volume, or multi-process welding. Therefore, you will need to evaluate your specific production needs before investing carefully.

Source: https://www.dobot-robots.com/apply/welding.html

Applications of Desktop Robotic Welding

Desktop robotic welding is practical in industries that require high precision, consistency, and space-efficient automation. Its compact form makes it ideal for low- to medium-volume production, prototyping, and specialized part manufacturing. Here are some real-life examples:

-

Electronics manufacturing: Manufacturers use desktop robotics to create precise, repeatable welds on battery cells and tabs. Common examples include welding battery tabs, sensor housings, shielded enclosures, or connectors.

Source: https://www.newscientist.com/

-

Medical device manufacturing: Desktop robotics often joins fine titanium or stainless-steel components of surgical instruments, implantable devices, catheter tips, or stainless steel tubes. High quality and precision mean welds are smooth, biocompatible, and within microscopic tolerances.

-

Automotive prototyping and component assembly: R&D teams within large auto companies use desktop robotic welders to create one-off parts or prototypes. Typical applications include making custom brackets, sensor mounts, thin-wall tubing, and prototype exhaust components.

-

Aerospace and defense industry: Aerospace labs use desktop laser welders to join aluminum or titanium alloy components. These involve welding lightweight metal components for UAVs, satellites, or precision assemblies.

-

Jewelry and watchmaking: A luxury watchmaker uses desktop robotic laser welding to assemble delicate parts, such as fine metal parts, clasps, bezels, or watch case components.

-

Custom metal fabrication: Fabricators use desktop robotics to quickly weld brackets, sheet metal parts, as well as tools, fixtures, enclosures, or decorative elements.

-

Educational applications: Technical universities utilize desktop robotic welding to provide students with hands-on experience in programming, robotics, and process control.

Desktop robotic welding is used in educational applications.

Source: https://robots-blog.com/

Welding Cobots - Combining the Best of Both Worlds

Welding cobots, or collaborative robots, are another emerging trend in welding automation. They are often scaled down to small-batch, semi-automated environments like desktop robotic welding. Welding cobots are designed to work alongside human operators, offering a safe and efficient way to automate welding tasks.

Most welding cobots are larger than desktop systems, designed for manual collaboration and work on larger parts. However, manufacturers use compact cobot systems on rolling carts in similar environments and offer similar benefits, such as flexibility, ease of programming, and smaller footprints.

Some cobots can approach desktop scale, especially if paired with a compact welding source and table-mounted fixture. However, welding cobots is not inherently part of desktop robotic welding.

If your priority is precision in a confined space, desktop robotic welders are better suited. If you want collaboration with a human operator and a little more range, cobots are ideal.

Welding Cobots Process

Source: https://www.universal-robots.com/

Final Thoughts

As automation becomes more accessible, desktop robotic welding has emerged as a crucial step toward more innovative and more agile manufacturing, even in small spaces. This technology provides a compact, precise, and efficient solution for small-scale welding tasks across various industries, including electronics, medical devices, automotive research and development, and custom fabrication.

By automating complex welds in a minimal footprint, desktop robotic welding ensures consistent quality, reduces human error, and facilitates rapid prototyping or low-volume production.

While it may not replace large-scale industrial systems or handle heavy-duty applications, its affordability, ease of use, and versatility make it an ideal choice for workshops, laboratories, and educational environments.

Desktop robotic welding setup for compact, high-precision tasks.

Source: https://newsroom.cisco.com/

🧐What Is Desktop Robotic Welding? FAQ

👏 You may be interested in the following:

Leave a comment