What is Spot Welding, and How Does It Work?

Spot welding is a resistance welding method widely used to join sheet metal in the automotive, battery, and auto-body industries. Instead of an arc, this method uses pressure and heat to form small welds in the form of a spot or nugget.

Generally, spot welding is quite a straightforward method, but the final results can vary in parameters that differ from those of traditional arc welding methods. Our primary objective is to answer commonly asked questions: What is spot welding, how does it work, how to spot weld, and what are its advantages?

What Is Spot Welding?

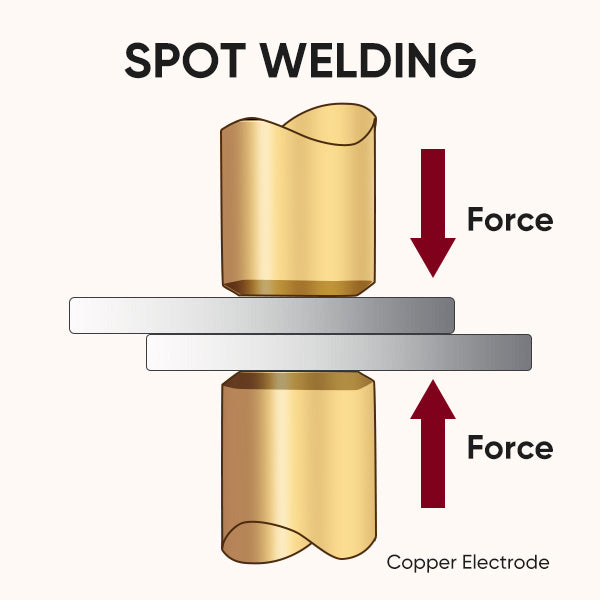

Spot welding is a unique resistance welding method based on the electrical resistance of copper electrodes and welded materials. Unlike the electric arc in processes such as TIG or MIG welding, spot welding uses high electrical current caused by the resistance of metals and controlled pressure to join two metal pieces seamlessly.

Keep in mind that spot welding doesn't produce the typical weld bead. It creates a molten nugget or a spot, hence the name. Welds are typically found on flanges, staggered in a single row of consecutive welds.

How Does A Spot Welding Work?

Spot welding, in most cases, uses a copper electrode to conduct current. Copper is the most suitable metal for this because it has high thermal conductivity and low electrical resistance compared to most other metals. However, welders also use tungsten or molybdenum in extremely high-current applications.

These electrodes clamp and apply pressure to the two pieces to conduct the current. Due to the low electrical resistance of the copper, the current freely passes. But once you add two sheets of metal you want to weld and pressure them, it creates a spot with high resistance.

Source: https://www.tuffaloy.com/resources/blog/welding-defects/5-common-welding-defects-and-how-to-prevent-them

Due to high resistance, the current reaches 2000 amps, producing extreme heat. The heat, combined with pressure, melts and fuses the two pieces at the point where the two electrodes merge. This entire process happens in a 1/2 or 3/4 of a second. The bond is strong, and with added speed, many industries favor resistance spot welding.

Parts Of Spot Welding System

Spot welding is a relatively straightforward system that is simple to master. To make welds, you will need a spot welder and electrodes.

Spot Welder is typically a simple little transformer machine. The welder transforms high voltage/low current from the outlet into a high current/low voltage power. This high current can reach more than 5000 amps, which is enough to melt and fuse the pieces into the joint. Most simple machines have manual control, meaning you control the current, pressure, and weld time by hand. However, advanced machines provide a set of pre-programmable and digital parameters, allowing for easy automation. Automated spot welding is standard in the automotive industry.

Electrodes in spot welding provide proper pressure and promote current flow. Copper is the most common electrode material, but welders also use tungsten and molybdenum due to their high melting point. Heat resistance is crucial in high-current applications where heat can melt virtually any metal. Regardless of the type, electrodes can have adjustable lengths, and tips sharpened to 3/16″. The tip geometry of the electrode tip can play an essential role in welding, so you should sharpen it once it reaches 1/4″ diameter.

How To Spot Weld

Spot welding occurs in a sequence that happens in four phases:

The first step in spot welding is aligning the pieces. Alignment reminds us of weld preparation, where you have to ensure a proper fit-up. Since there is no filler metal, you shouldn't leave any gap between the pieces.

You must plan your welds to avoid distortion or warping of sheet metal. Once joined, the bond is strong, so if there is any mistake in alignment, you will need to rework it. Also, you will need to align the two copper electrodes so that they form a perfect path for welding current and focus the heat in a small dot.

Next, you must apply the pressure to the metal sheets. The two tongs clamp the pieces, but you need to be careful. The more pressure you use, the lower the overall heat in the joint. So, you will need to adjust this parameter according to the material and thickness of the metal you are welding.

Finally, you flip on the switch, and the electrical current commences. The current passes through two electrodes, but once it meets the weld pieces, it creates resistance. The resistance generates heat, which melts the sheets, and with applied pressure, two pieces fuse.

The entire process happens very fast, typically in 1/2 or 3/4 of a second. Once you've spent enough time, you stop the current and release the pressure. As a result, you can create strong spot welds in seconds, which makes it highly appreciated in any industry that uses sheet metal.

Welding Parameters Of Spot Welding

Spot welding is not dependent on traditional welding parameters such as the amperage, voltage, arc length, or travel angle. Instead, the results of spot welding are dependent on:

- Pressure

- Squeeze time

- Welding Current

- Weld Time

- Cool time

All four parameters are closely related to the stages of spot welding. Advanced spot welders will allow you to set each of these, but with the basic units, you will have to control most of them manually.

Nonetheless, let's further explain how they can affect the properties of the spot weld.

The Spot Welding Pressure

As noted above, the amount of force you apply can directly impact the heat you use on your welding joint. The more you squeeze the electrodes, the deeper they penetrate the weld joint and the larger the contact area.

As the contact area is larger, the current is less focused, and the resistance is lower. The lower the resistance of the welding joint, the less heat focuses on the pieces.

Meanwhile, too little pressure is also not suitable. Besides the resistance, you will need the pressure to fuse the molten pieces. Therefore, inadequate pressure will focus heat only on the surface, and you won't get a proper penetration.

Source: https://avioweld.com/resistance-welding/principle/

The key to successful spot welding is finding the sweet spot in the pressure you apply. Some advanced spot welders will automatically apply pressure according to the parameters you input. Generally, the pressure depth on the sheet surfaces should always be at most 25 percent of the sheet metal thickness.

Squeeze Time In Spot Welding

The squeeze time in spot welding is the time spent from applying the pressure to starting a welding current. This parameter can also affect the overall welding results.

Running the current in spot welding immediately after clamping the pieces can create various defects. Some of the most common ones are arching, premature electrode wear, or interfacial expulsion. Giving electrodes time to sink in the pieces and settle before initiating the current can help you deal with most of these issues.

While you will need to use some squeeze time, you don't want to spend too much time. The more time welding pieces are squeezed wouldn't give you better results or strong welds. Instead, you will be wasting your time, and with high force, it can cause initial distortion.

Weld Time In Spot Welding

The weld time in spot welding is the time between the start and the end of the welding current. Similar to traditional welding methods, the more time you expose the joint to the heat, the more base metal will melt to a point where you burn holes through it.

One of the challenges of spot welding is that weld time can be hard to determine. Most home spot welders provide manual control, so you will have to count. However, advanced machines use digital controls that allow you to precisely set the number of cycles that pass through the pieces before stopping. Precise digital control is crucial in achieving solid and repetitive welds in automated spot welding.

Adjusting the weld time in spot welding is typically based on the thickness of the metal you are joining. Thin sheets will need 1/2 or 3/4 of a second of current or less. The key is to find a balance where you properly fuse and penetrate the pieces without burning through them or creating cold welds without proper penetration.

Welding Current

Welding current and welding time in spot welding are inversely proportional. The more current you have, the less time you spend welding. The less heat you have, the more time you'll have to commit welding until you reach the melting temperature.

To calculate the welding temperature in spot welding, you can use an equation:

Welding Temperature= i2 x t x R.

In this equation, i= a welding current, t= welding time, and R= material resistance. You set up the welding current and control the welding time, while resistance depends on the metal types and thickness.

Even though you can control the current and welding time, you must be careful. Low current requires more time, which can overheat the welding tools and the welder's transformer. High current, although it requires less time, can cause the expulsion of molten metal spraying from the weld joint.

Cooling Time In Spot Welding

The cool time refers to the time after you stop the welding current and release the pressure on base metal sheets. Like with squeeze, spending a second or two before releasing the pressure can have several benefits.

The thermal properties of copper electrodes dissipate the excess heat after the welding. Heat extraction prevents overheating and heat distortion. In addition, removing the excess heat from the joint also stops the molten nugget from reacting with atmospheric gases.

However, you should also avoid using a long cooling time in spot welding. While copper electrodes disperse excessive heat, there is a point at which they start melting. As a result, you can damage or contaminate the electrode tip. Additionally, extended cooling time can produce brittle welds on low-carbon steel.

What Metals Can You Spot Weld?

Technically, you can spot-weld any metallic material. But if we remember the basics of this resistance welding, the most suitable metals are the ones with high electrical resistance and low thermal conductivity. Some of the most commonly spot-welded metals are:

Let's discuss some common metals you could regularly encounter in your workshop and work on with your spot welder.

Spot Welding Carbon Steel

Carbon steel is generally one of the most accessible metals to weld. Its low thermal conductivity and high electrical resistance make it perfect for most spot welding applications.

However, the results might vary depending on the amount of carbon content. Mild steel, or low-carbon steel, is typically the easiest to weld, but as the carbon content increases, its fracture toughness decreases. High-carbon steel welds become prone to cracks or failure, so you should be careful before welding.

Spot Welding Galvanized Steel

Galvanized steel is actually zinc-coated steel. A layer of zinc gives regular steel corrosion resistance, but it slightly affects its metallurgical and welding properties.

Galvanized steel is more challenging to weld compared to carbon steel. Besides the toxic fumes, burning a zinc coating can rapidly degrade the copper electrodes. Zinc has a low melting point, so it starts to boil and melt before the steel, causing contamination of electrodes. Due to this layer, you will need some more heat to weld galvanized steel successfully.

Spot Welding Aluminum

Aluminum is one of the notorious metals when it comes to welding, and spot welding is no exception. Aluminum and its alloys are increasingly popular in industries due to their low weight and high strength, but their thermal properties make them challenging to spot.

Although aluminum has thermal conductivity and electrical resistance similar to copper, its low resistance makes it hard to spot weld. As a result, you must use two or three times higher current compared to steel or copper.

Besides being rare in the regular welding market, high currents can cause excessive electrode degradation. After a few welds, you will need to replace or change tips, which is why aluminum spot welding is reserved only for specialized industries.

Spot Welding Copper

Although you can successfully spot-weld copper, you will need specialized equipment and, most importantly, the electrodes. Welding copper with copper electrodes won't do you too much good. The pieces tend to weld to electrodes, so you will need a different approach.

That's why spot welding copper requires specialized electrodes made of molybdenum and tungsten. Tungsten has the highest melting point, so it can withstand applying enough heat necessary to melt and fuse copper pieces.

Spot Welding Nickel

Nickel is a widely used material for battery strips. An entire series of tiny spot welders is designed to weld batteries. Nickel in battery strips shows good corrosion resistance and mechanical properties while being much easier and cheaper to spot weld than aluminum or copper.

Other materials commonly spot welded include stainless steels (particularly austenitic and ferritic) and titanium. However, these are metals you will rarely deal with in your garage and home shop, and the key to spot-welding them is only to adjust to their thermal and electrical properties.

Spot Welding Applications

Spot welding's efficiency and ability to create strong joints quickly make it widely used worldwide. This method has applications in several industries, such as aerospace, automotive, rail, white goods, metal furniture, electronics, medical buildings, and construction.

Some of the most common examples of spot resistance welding include:

- Welding sheet metal parts in car bodies, including doors, hoods, and frames

- Joining thin sheets of aluminum and other alloys in the construction of aircraft fuselages and wings

- Assembling parts of refrigerators, washing machines, and air conditioners

- Connecting battery packs in various devices, including laptops, smartphones, and electric vehicles

- Joining parts of metal chairs, tables, and cabinets

- Joining metal sheets and components in the construction of train carriages and other railway vehicles.

The advantages of spot welding are:

- Versatile Method: Spot welding can join most metallic materials, such as mild steel, nickel alloys, titanium, stainless steel, aluminum, or galvanized steel.

- Fast and Efficient: Spot welders utilize much less power than MIG or TIG welding machines to produce high-strength welds. Additionally, you can finish spot welding in a second, which is ideal for mass production of the parts.

- Straightforward: spot welding is a relatively straightforward method. There aren't too many welding parameters, so training personnel is also accessible.

- Suitable For Thin Metal Welding: Resistance spot welding produces the highest-quality welds on sheet metal. Skill requirements are much lower, and the risk of thermal defects on sheets is low.

- Consistent results: With pre-customed parameters, spot welding can yield controlled, repeatable welds each time, which is again suitable for mass production.

- Low Cost: High efficiency and speed also mean lower costs. Overall, spot welding equipment is relatively cheap, especially compared to other methods used in sheet metal welding.

The drawbacks of Spot Welding Are:

- Limited Weld Desing: Spot welding is most suitable for lap joints. Any other designs can be complicated to pull off, especially when another side of the material is not accessible.

- Not Suitable For Thick Metals: Spot welding falls short when dealing with thicker materials. It works best with 1/8-inch or lower gauge metals, and weld strength is significantly lower in thick materials.

- Vulnerable To Fluctuations: The spot welder transforms high voltage, low current electricity from an outlet into a low voltage and high current power used for welding. Voltage fluctuations can severely affect the welding power and consistency.

- Health Risks: Although there are no high amounts of radiation or sparks, heat and fumes still present a health hazard.

Tips For Successful Spot Welding

Instead of a usual conclusion, we left the end of our article with some tips for successful spot welding. These tips will help you if you are having some common Spot welding issues such as weak welds, surface splash, or electrode sticking.

- Choose the right electrode: Choosing the right electrode is essential in any spot welding application. While copper electrodes are suitable for most of your home applications, switching to metals such as copper will require a different approach.

- Align the electrodes: Before even starting to spot weld, check if your electrodes are aligned. Well-aligned electrodes promote proper current flow.

- Check Part Fitup: Spot welding doesn't use a filler metal. The parts must fit tightly, with no gap between them.

- Adjust electrode force: The force should be high enough to promote good penetration but not high enough to produce surface splashes or sticking.

- Allow squeeze time: The squeeze time is sufficient to reach the set force before the weld current flows.

- Adjust weld time: You should adjust the weld time according to the thickness of the metal you are welding.

- Clean pieces before welding. Dirt, rust, oil, or paint can cause undue surface heating, which can cause contaminants to boil, spatter, or cause penetration issues.

- Clean electrode before welding: Heavy contamination buildup on the electrodes can cause excessive surface heating. While you should expect some contamination, thick layers can create highly inconsistent welds.

- Shorter tongs create more heat: Long tongs tend to bend or misalign. Poor pressure and improper current geometry can affect the overall heat in the joint.

🧐What is Spot Welding, and How Does It Work FAQ

1. What is Spot Welding and How Does it Work?

Spot welding is a resistance welding technique that uses electrical current and pressure to join metal pieces. Copper electrodes clamp the metals together, and when current passes through, resistance at the contact point generates intense heat. This heat melts and fuses the metals, creating a small “spot” weld. The process is quick, typically taking less than a second, and is favored in industries for its efficiency and strong bond.

2. How to spot weld?

Spot welding involves four key steps:- Alignment: Align the metal pieces carefully, ensuring there are no gaps, as spot welding doesn’t use filler metal. Also, align the copper electrodes to create a precise weld path.

- Applying Pressure: Clamp the metal sheets with the electrodes. Adjust the pressure based on the material and thickness, as more pressure reduces the heat at the joint.

- Starting Electrical Current: Turn on the current, which passes through the electrodes. The resistance at the weld point generates heat, melting the metal and fusing the pieces.

- Releasing: The process happens quickly, usually within 1/2 to 3/4 of a second. Stop the current and release the pressure to complete the weld.

👏 You may be interested in the following:

Leave a comment